Polycarbonate Milling Techniques And Polycarbonate Sheet Price

Polycarbonate Sheet Price

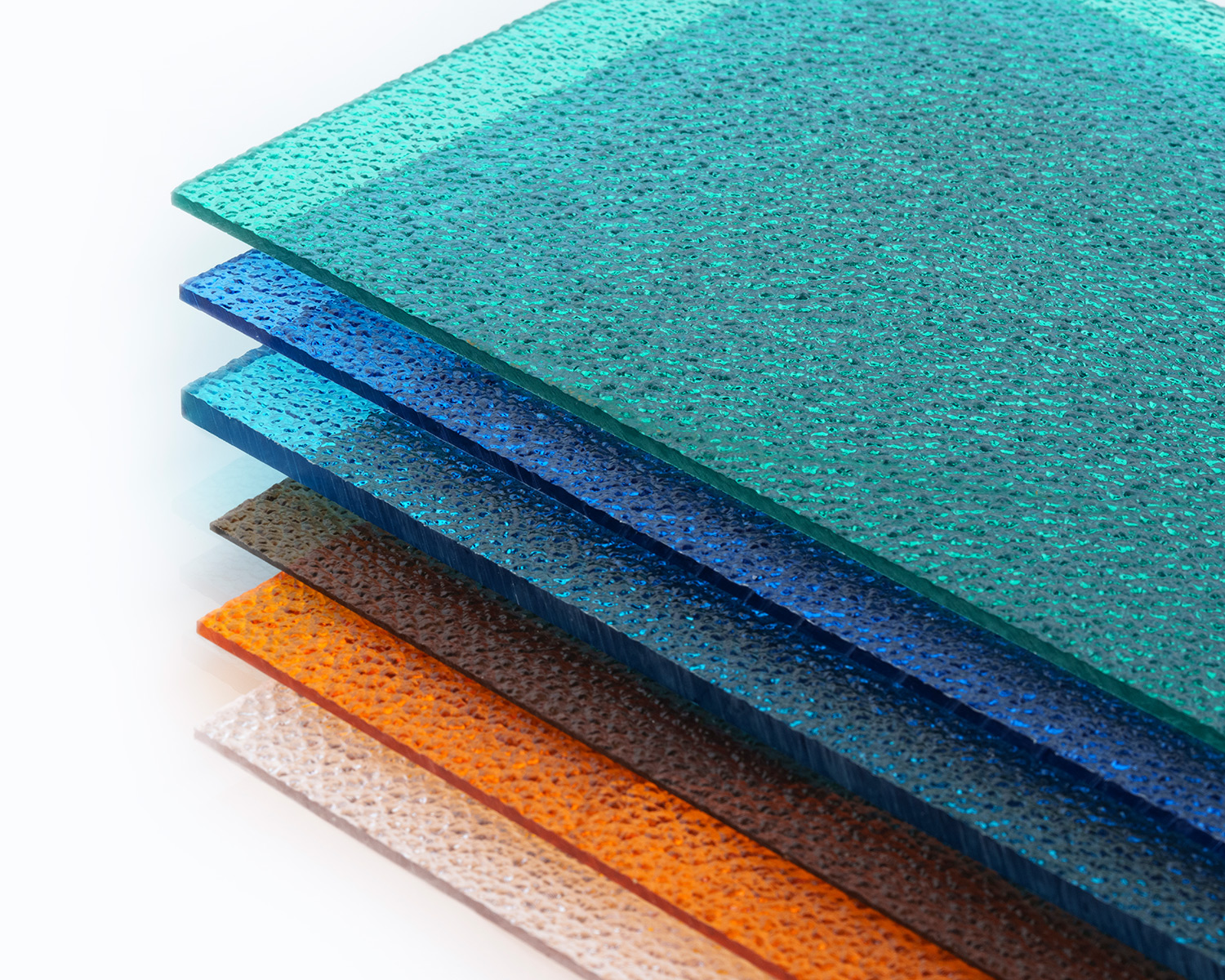

Polycarbonate (PC) is a thermoplastic and is widely used in many applications. It is a good insulator, heat resistant and has flame retardant properties therefore it is used in power systems and telecommunications. It is durable and light and is used in the construction material. It is used in 3D printing, data storage, security components and more.

It is easy to make parts from PC as it is easy to fabricate. The different fabrication processes that can be used with PC are cutting, bending, milling, sanding, polishing, finishing, bonding and sheet printing.

Polycarbonate is virtually unbreakable and has a high impact strength. Polycarbonate sheet price is less when compared to that of glass. It can also be easily moulded or thermoformed to make parts.

Milling techniques

Milling is used to add precision features to the fabricated PC part. Milling cutters are used for this. The milling process can be used along with a CNC routing machine which is used to make holes in the parts. Advanced machines are used for milling to get consistency and close tolerances.

Milling is done by a milling technician who follows the proper procedure to achieve the correct output. The technician looks at all the operating conditions like the efficiency of the milling tool and the milling speed. These two factors determine the quality of the final output.

Depending on the final output the approach is decided. PC does not lose heat fast as the other materials therefore you should avoid localised overheating during the milling process. To achieve the desired result the following rules need to be followed:

- Check the milling machine and ensure that the machine is in good working condition. Check the axis motors, controller box, tool bit, spindle shaft, spindle motor, vertical column and safety shield.

- The milling process produces heat and an inert coolant is required. The inert coolant will not react with PC and help to lower the temperature.

- The PC chips produced should be removed by consistently blowing air or coolant.

A CNC routing machine can be used for curved and irregular surfaces as it produces smooth finishes. The tolerance of errors can be controlled to 0.05mm. The factors to consider are the routing speed, feeding procedure, motor rating and the material used for the router bit like high-speed steel or carbide.

How polished PC surfaces are achieved?

To produce polished PC surfaces solvent vapours are used. This makes the final surface an optically clear surface. Vapour polishing offers benefits like an improved opaque and matt finish and gives a glossy look. For vapour polishing, you need to work with the polycarbonate technicians.

This allows PC to be used in applications where no obstruction to light is required. It also improves the applications of PC.