What Are The Different Processes Used In Acrylic Fabrication?

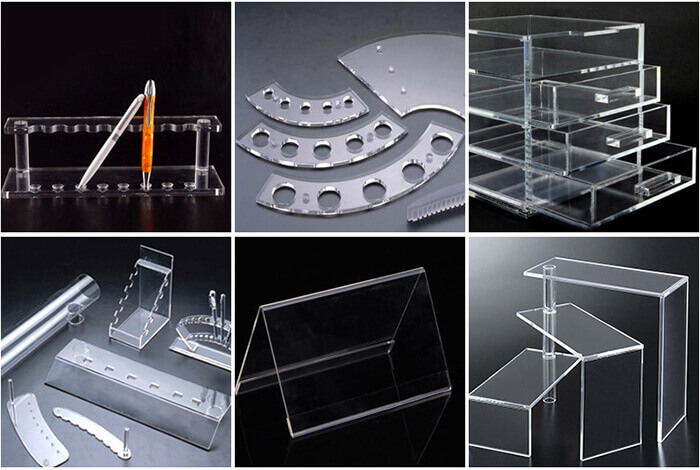

Acrylic fabrication | Image Resource: mdeplastics.com

Acrylic is an engineering plastic and is also known as PMMA, Plexiglas, Lucite, Acrylic glass and more. As it is durable, lightweight and transparent, it is used as an alternative to glass. It is scratch-resistant, temperature-resistant, impact-resistant, and weather-resistant and has low heat loss.

Acrylic is a perfect alternative to glass and offers more colour and size options. It is easier to work with, and it is like unbreakable glass. It is environmentally stable and superior to other plastics. It is a preferred material for various outdoor applications. Additives can be added to modify properties when required.

The different processes used in acrylic fabrication start with storage, handling, masking removal, cleaning, cutting, annealing, finishing, cementing, decorating and forming.

Different processes

Acrylic is a combustible plastic and can catch fire if it comes in contact with any source of ignition. Acrylic sheets are best stored horizontally in a well-ventilated and consistent temperature area.

The sheet is covered with paper masking or polyethylene film for protection during storage and fabrication. This is called masking.

To remove the masking, start from the edge and peel away from the sheet. If it is difficult to remove, then you can use 50% rubbing alcohol with water and spray on the edges. Pull the masking away from the sheet.

PMMA can be cleaned with a mild soap solution or commercially available plastic cleaner and a cloth.

To cut the sheet, various cutting tools can be used. The different cutting tools are table and panel saws, routers, CNC routers and CNC laser cutters. A drilling machine can be used to drill holes in acrylic.

Various methods are used to get the desired edge finish. Shapers and routers can be used for decorative edges. Jointers are used to prepare the edges for cementing and hand finishing. Edge finishing machines can be used to produce an edge with a polished look and for cementing.

Annealing is done to reduce the possibility of crazing, which occurs due to the internal stresses caused by cutting and machining. It is recommended to avoid any fissures from forming during cementing, bending and forming.

Finishing is done to get the required edge finish. The different methods used in finishing are scraping, sanding, buffing and flame polishing.

Cementing is done to well-machined parts to produce a strong and attractive joint and minimise the chances of 'Blushing'. Different types of cement used are solvent cement, mixed solvent cement and polymerisation cement.

PMMA sheets can be easily decorated with paints specially made for acrylic or vinyl. The different methods used are spray-painting, screen printing, hot stamping and more.

Forming is used to get the desired shape. The various methods used are cold forming, line bedding, thermoforming, drape forming, oven sheet forming and free-blown forming.